+86-13564731919

sales@forged-fittings.com

Products List

Products List

|

|

| ASTM A182 F304/F304L 3000LB Socket Weld Elbow | ASTM A105 6000LB Socket Weld Elbow |

|

|

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/2″NB TO 4″NB IN |

| Class | 3000 LBS, 6000 LBS, 9000 LBS |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

| Stainless Steel | ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L |

| Duplex & Super Duplex Steel | ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950. |

| Carbon Steel | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C |

| Alloy Steel | ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91 |

| Copper Alloy Steel | ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30) |

| Nickel Alloy Steel | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) |

|

|

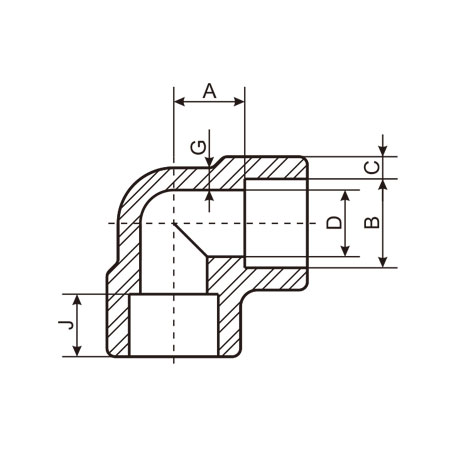

| DN |

Nom. Pipe Size |

Center to Bottom of Socket-A |

Socket Bore Dia. B |

Bore Dia.Of Fitting D |

Socket Wall Thickness(2) C |

Body Wall Thickness G |

Depth of Socket Min. J |

||||||||||||||

|

90°Elbows Tees,Crosses |

45°Elbows | Class Designation | Class Designation | ||||||||||||||||||

| Class Designation | Class Designation | Class Designation | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | Ave. | Min. | Ave. | Min. | Ave. | Min. | Min. | Min. | Min. | ||||

| 6 | 1/8" | 11.0 | 11.0 | --- | 8.0 | 8.0 | --- | 10.8 | 6.9 | 4.0 | --- | 3.18 | 3.18 | 3.96 | 3.43 | --- | --- | 2.41 | 3.15 | --- | 9.5 |

| 8 | 1/4" | 11.0 | 13.5 | --- | 8.0 | 8.0 | --- | 14.2 | 9.3 | 6.4 | --- | 3.78 | 3.30 | 4.60 | 4.01 | --- | --- | 3.02 | 3.68 | --- | 9.5 |

| 10 | 3/8" | 13.5 | 15.5 | --- | 8.0 | 11.0 | --- | 17.6 | 12.6 | 9.2 | --- | 4.01 | 3.50 | 5.03 | 4.37 | --- | --- | 3.20 | 4.01 | --- | 9.5 |

| 15 | 1/2" | 15.5 | 19.0 | 25.5 | 11.0 | 12.5 | 15.5 | 21.8 | 15.8 | 11.8 | 6.4 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 |

| 20 | 3/4" | 19.0 | 22.5 | 28.5 | 13.0 | 14.0 | 19.0 | 27.2 | 21.0 | 15.6 | 11.1 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 |

| 25 | 1" | 22.5 | 27.0 | 32.0 | 14.0 | 17.5 | 20.5 | 33.9 | 26.7 | 20.7 | 15.2 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 |

| 32 | 1-1/4" | 27.0 | 32.0 | 35.0 | 17.5 | 20.5 | 22.5 | 42.7 | 35.1 | 29.5 | 22.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 |

| 40 | 1-1/2" | 32.0 | 38.0 | 38.0 | 20.5 | 25.5 | 25.5 | 48.8 | 40.9 | 34.0 | 28.0 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 |

| 50 | 2" | 38.0 | 41.0 | 54.0 | 25.5 | 28.5 | 28.5 | 61.2 | 52.5 | 42.9 | 38.2 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 |

| 65 | 2-1/2" | 41.0 | --- | --- | 28.5 | --- | --- | 73.9 | 62.7 | --- | --- | 8.76 | 7.67 | --- | --- | --- | --- | 7.01 | --- | --- | 16.0 |

| 80 | 3" | 57.0 | --- | --- | 32.0 | --- | --- | 89.8 | 78.0 | --- | --- | 9.52 | 8.30 | --- | --- | --- | --- | 7.62 | --- | --- | 16.0 |

| 100 | 4" | 66.5 | --- | --- | 41.0 | --- | --- | 115.2 | 102.3 | --- | --- | 10.69 | 9.35 | --- | --- | --- | --- | 8.56 | --- | --- |

16.0 |

| Marking & Packing |

| Products are packaged to ensure that there is no damage during transit. In case of exports, the standard export packaging is done in wooden cases. All forged fittings are marked with Grade, Lot No, Size, Degree, and our trademark. On special requests, we can also, make custom marking on our products. |

|

Quality Assurance

|

| At MetalGoods, all fittings and flanges are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products. |

|

Test Certificates

|

| Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. |