![qua_banner[2019-06-02 13:23:20]

qua_banner[2019-06-02 13:23:20]](/Upload/banner-quality.jpg)

Quality

Our products are manufactured and tested in accordance to ASTM, ASME, ANSI, MSS and other applicable industry codes and specifications.Material Certifications are available upon request to the applicable ASTM/ASME material specifications for all Forge fittings.Chemical and mechanical properties of every MetalGoods Forge product are fully traceable to the original forging lot and raw material heat. Modern machining equipment plus rigid inspections of all parts assures dimensional accuracy. Quality Assurance procedures include, 100% hydrostatic and pneumatic testing of all forged fittings that fully comply to applicable ASTM/ANSI standards and industry codes.

In order to make the inspection result more dependable, various Non-Destructive Testing (NDT) methods are used, such as: Visual Inspection, Dimension Checking, Chemicial Analysis, Petranent Testing (PT), Maganetic Particle Testing (MT) , Eddy Current Testing (ET) , Ultrasonic Testing (UT) , Radiographic Testing (RT) , In-Situ Metallography Leak Testing, Hardness Test and so on. For some of the special test items which can't be done by our labs, we will send to a notary public lab for further result.

|

|

|

|

Material Analysis |

Carbon Sulfur Analyzer |

Surface Finish Testing |

|

|

|

|

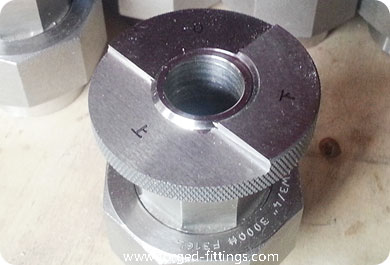

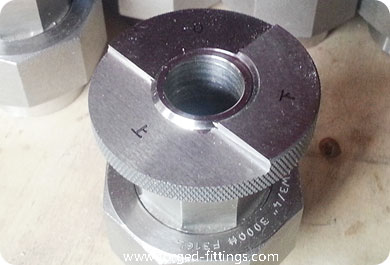

Threaded Testing |

Petranent Testing(PT) |

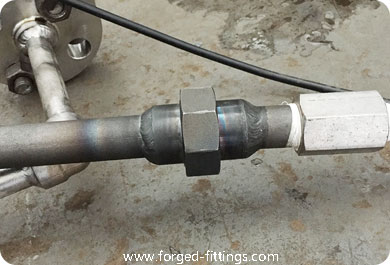

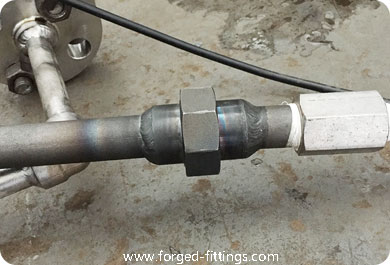

Hydrostatic Testing |

|

|

|

|

Spectral analysis(PMI) |

Hardness Testing |

Impact Test |