+86-13564731919

sales@forged-fittings.com

Products List

Products List|

Size: 1/8” NPS TO 8” NPS, DN8 TO DN200

Type: Concentric Swage Nipples, Eccentric Swage Nipples

Dimensions: MSS SP-95-2006, BS 3799

Connection Ends:

BBE = bevel both ends TBE = thread both ends

PBE = plain both ends GBE = grooved both ends

TXG = thread by groove TXB = thread by bevel

PXG = plain by groove BXT = bevel by thread

TLE: Thread large end PLE: Plain large end

BLE: Bevel large end PSE: Plain small end

BSE: Bevel small end TSE: Thread small end

Raw Materials: A106 Gr. B Seamless Pipes, A105/A105N Bars, A182 304/304L Bars, A182 316/316L Bars, A312 304/304L Seamless Pipes, Duplex Seamless Pipes, A312 316/316L Seamless Pipes, A350-LF2, Alloy Steel Seamless Pipes/Bars

Thickness: Standard, Extra Heavy, Schedule 160, or Double Extra Heavy

Ends: Beveled, Square Cut (for socket-weld), NPT/BSPT/BSP Threaded Swages, Customer Specification

Stainless Steel Swage Nipples/Swage – MSS-SP-95 :

304, 304L, 304H, 316, 316L, 317, 317L, 321, 310, 347, 904L, 2205 Duplex

Carbon Steel Swage Nipples/Swage – MSS-SP-95 :

Carbon Steel ASTM A105, A350 LF2, A106 Gr.B, A234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

NPT Threads conform to ASME B1.20.1

ASTM/ASME A105/SA105 The dimensions for forged carbon steel fittings conform to ASME B16.11

Alloy Steel Swage Nipples/Swage – MSS-SP-95 :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

A105/A105N Forged Fittings, A182 Forged Fittings

Nickel Alloy Swage Nipples/Swage – MSS-SP-95 :

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Duplex & Super Duplex Swage Nipples/Swage – MSS-SP-95 :

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462

|

|

|

|

|

|

|

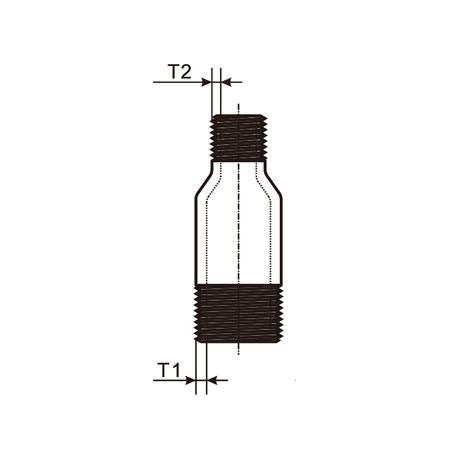

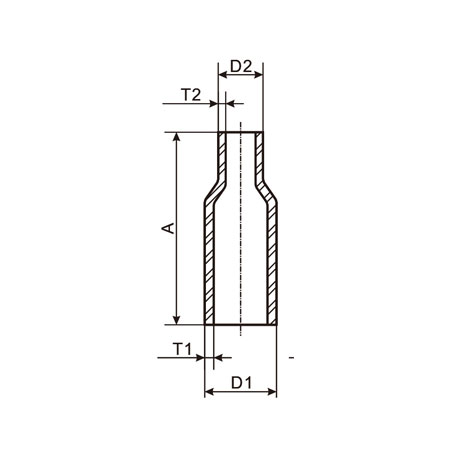

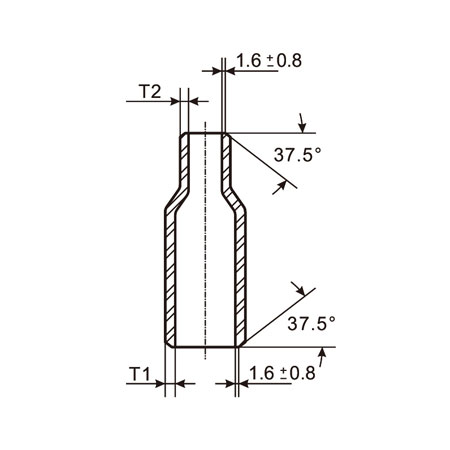

| Concentric Swage Nipple (TBE) | Concentric Swage Nipple (PBE) | Concentric Swage Nipple (BBE) |

|

|

|

|

|

|

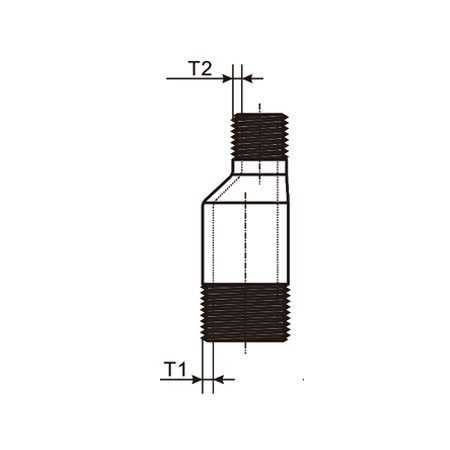

| Eccentirc Swage Nipple (TBE) | Eccentirc Swage Nipple (PBE) | Eccentirc Swage Nipple (BBE) |

|

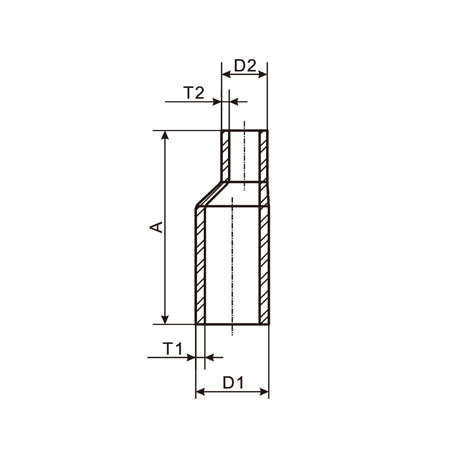

Nom. Pipe Size (NPS) |

Outside Diameter |

End To End “A” |

Wall Thickness | ||||||||

|

Large End D1 |

Small End D2 |

T1 | T2 | ||||||||

|

Sch40 (STD) |

Sch80 (XS) |

Sch160 | XXS |

Sch40 (STD) |

Sch80 (XS) |

Sch160 | XXS | ||||

| 1/4"×1/8" | 13.7 | 10.3 | 57 | 2.2 | 3.0 | 3.7 | 6.1 | 1.7 | 2.4 | ||

| 3/8"×1/8" | 17.1 | 10.3 | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 1.7 | 2.4 | ||

| 3/8"×1/4" | 17.1 | 13.7 | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 2.2 | 3.0 | ||

| 1/2"×1/8" | 21.3 | 10.3 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 1.7 | 2.4 | ||

| 1/2"×1/4" | 21.3 | 13.7 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.2 | 3.0 | ||

| 1/2"×3/8" | 21.3 | 17.1 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.3 | 3.2 | ||

| 3/4"×1/8" | 26.7 | 10.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 1.7 | 2.4 | ||

| 3/4"×1/4" | 26.7 | 13.7 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.2 | 3.0 | ||

| 3/4"×3/8" | 26.7 | 17.1 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.3 | 3.2 | ||

| 3/4"×1/2" | 26.7 | 21.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1"×1/8" | 33.4 | 10.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 1.7 | 2.4 | ||

| 1"×1/4" | 33.4 | 13.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.2 | 3.0 | ||

| 1"×3/8" | 33.4 | 17.1 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.3 | 3.2 | ||

| 1"×1/2" | 33.4 | 21.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1"×3/4" | 33.4 | 26.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4"×1/8" | 42.2 | 10.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 1.7 | 2.4 | ||

| 1-1/4"×1/4" | 42.2 | 13.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.2 | 3.0 | ||

| 1-1/4"×3/8" | 42.2 | 17.1 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.3 | 3.2 | ||

| 1-1/4"×1/2" | 42.2 | 21.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1-1/4"×3/4" | 42.2 | 26.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4"×1" | 42.2 | 33.4 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2"×1/8" | 48.3 | 10.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 1.7 | 2.4 | ||

| 1-1/2"×1/4" | 48.3 | 13.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.2 | 3.0 | ||

| 1-1/2"×3/8" | 48.3 | 17.1 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.3 | 3.2 | ||

| 1-1/2"×1/2" | 48.3 | 21.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1.1/2"×3/4" | 48.3 | 26.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/2"×1" | 48.3 | 33.4 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2"×1-1/4" | 48.3 | 42.2 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2"×1/8" | 60.3 | 10.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 1.7 | 2.4 | ||

| 2"×1/4" | 60.3 | 13.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.2 | 3.0 | ||

| 2"×3/8" | 60.3 | 17.1 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.3 | 3.2 | ||

| 2"×1/2" | 60.3 | 21.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 2"×3/4" | 60.3 | 26.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 2"×1" | 60.3 | 33.4 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.4 | 4.5 | 6.4 | 9.1 |

| 2"×1-1/4" | 60.3 | 42.2 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2"×1-1/2" | 60.3 | 48.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.7 | 5.1 | 7.1 | 10.2 |

| 2-1/2"×1/8" | 73.0 | 10.3 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 1.7 | 2.4 | ||

| 2-1/2"×1/4" | 73.0 | 13.7 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.2 | 3.0 | ||

| 2-1/2"×3/8" | 73.0 | 17.1 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.3 | 3.2 | ||

| 2-1/2"×1/2" | 73.0 | 21.3 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.8 | 3.7 | 4.8 | 7.5 |

| 2-1/2"×3/4" | 73.0 | 26.7 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 2.9 | 3.9 | 5.6 | 7.8 |

| 2-1/2"×1" | 73.0 | 33.4 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.4 | 4.5 | 6.4 | 9.1 |

| 2-1/2"×1-1/4" | 73.0 | 42.2 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2-1/2"×1-1/2" | 73.0 | 48.3 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.7 | 5.1 | 7.1 | 10.2 |

| 2-1/2"×2" | 73.0 | 60.3 | 178 | 5.2 | 7.0 | 9.5 | 14.0 | 3.9 | 5.5 | 8.7 | 11.1 |

| 3"×1/8" | 88.9 | 10.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 1.7 | 2.4 | 3.2 | 4.8 |

| 3"×1/4" | 88.9 | 13.7 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.2 | 3.0 | 3.7 | 6.1 |

| 3"×3/8" | 88.9 | 17.1 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.3 | 3.2 | 4.0 | 6.4 |

| 3"×1/2" | 88.9 | 21.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.8 | 3.7 | 4.8 | 7.5 |

| 3"×3/4" | 88.9 | 26.7 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.9 | 3.9 | 5.6 | 7.8 |

| 3"×1" | 88.9 | 33.4 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.4 | 4.5 | 6.4 | 9.1 |

| 3"×1-1/4" | 88.9 | 42.2 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.6 | 4.9 | 6.4 | 9.7 |

| 3"×1-1/2" | 88.9 | 48.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.7 | 5.1 | 7.1 | 10.2 |

| 3"×2" | 88.9 | 60.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.9 | 5.5 | 8.7 | 11.1 |

| 3"×2-1/2" | 88.9 | 73.0 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 5.2 | 7.0 | 9.5 | 14.0 |

| 3-1/2"×1/8" | 101.6 | 10.3 | 203 | 5.7 | 8.1 | 1.7 | 2.4 | ||||

| 3-1/2"×1/4" | 101.6 | 13.7 | 203 | 5.7 | 8.1 | 2.2 | 3.0 | ||||

| 3-1/2"×3/8" | 101.6 | 17.1 | 203 | 5.7 | 8.1 | 2.3 | 3.2 | ||||

| 3-1/2"×1/2" | 101.6 | 21.3 | 203 | 5.7 | 8.1 | 2.8 | 3.7 | 4.8 | 7.5 | ||

| 3-1/2"×3/4" | 101.6 | 26.7 | 203 | 5.7 | 8.1 | 2.9 | 3.9 | 5.6 | 7.8 | ||

| 3-1/2"×1" | 101.6 | 33.4 | 203 | 5.7 | 8.1 | 3.4 | 4.5 | 6.4 | 9.1 | ||

| 3-1/2"×1-1/4" | 101.6 | 42.2 | 203 | 5.7 | 8.1 | 3.6 | 4.9 | 6.4 | 9.7 | ||

| 3-1/2"×1-1/2" | 101.6 | 48.3 | 203 | 5.7 | 8.1 | 3.7 | 5.1 | 7.1 | 10.2 | ||

| 3-1/2"×2" | 101.6 | 60.3 | 203 | 5.7 | 8.1 | 3.9 | 5.5 | 8.7 | 11.1 | ||

| 3-1/2"×2-1/2" | 101.6 | 73.0 | 203 | 5.7 | 8.1 | 5.2 | 7.0 | 9.5 | 14.0 | ||

| 3-1/2"×3" | 101.6 | 88.9 | 203 | 5.7 | 8.1 | 5.5 | 7.6 | 11.1 | 15.2 | ||

| 4"×1/4" | 114.3 | 13.7 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.2 | 3.0 | ||

| 4"×3/8" | 114.3 | 17.1 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.3 | 3.2 | ||

| 4"×1/2" | 114.3 | 21.3 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 4"×3/4" | 114.3 | 26.7 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 4"×1" | 114.3 | 33.4 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.4 | 4.5 | 6.4 | 9.1 |

| 4"×1-1/4" | 114.3 | 42.2 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.6 | 4.9 | 6.4 | 9.7 |

| 4"×1-1/2" | 114.3 | 48.3 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.7 | 5.1 | 7.1 | 10.2 |

| 4"×2" | 114.3 | 60.3 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.9 | 5.5 | 8.7 | 11.1 |

| 4"×2-1/2" | 114.3 | 73.0 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.2 | 7.0 | 9.5 | 14.0 |

| 4"×3" | 114.3 | 88.9 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.5 | 7.6 | 11.1 | 15.2 |

| 4"×3-1/2" | 114.3 | 101.6 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.7 | 8.1 | ||

|

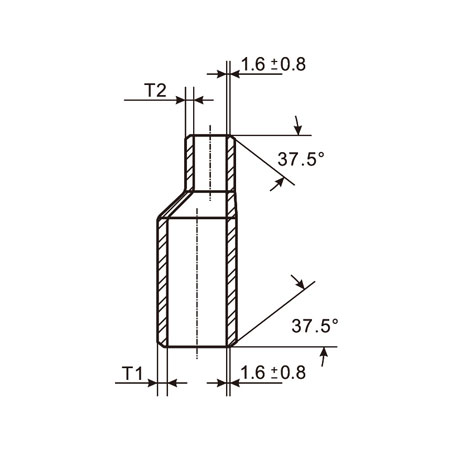

Nominal Pipe Size(inch) |

Overall Length (mm) |

Outside diameter at end | Wall Thickness (prior to threading or grooving) | ||||||

| Square Cut Ends(mm) | Other End Connection(mm) | ||||||||

| 1/8”to 3/8” | ±1.5 |

±0.4 0.8 |

±0.8 |

Not less than 87.5% of nominal wall thickness |

|||||

| 1/2”to 1-1/2” | ±1.5 |

±0.4 0.8 |

±1.5 0.8 |

||||||

| 2”to 2-1/2” | ±3.0 | ±0.8 |

±1.5 0.8 |

||||||

| 3”to 4” | ±3.0 | ±0.8 | ±1.5 | ||||||